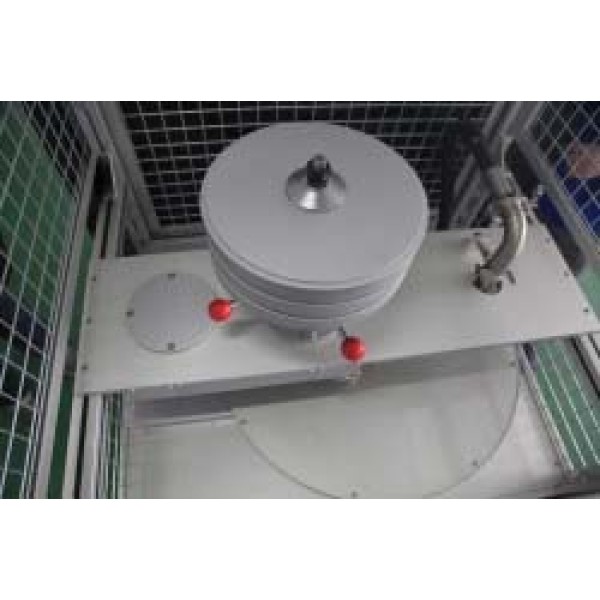

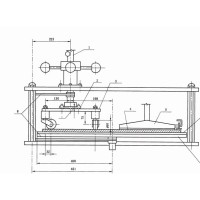

Resilient and laminate floor coverings - Castor chair tester

- Product Code: FCTM

Application:

Caster-resistant floor friction tester, also known as floor casters abrasion durability testing machine, floor casters friction durability testing machine, also known as castor-resistant floor effect tester, etc., this test is widely used to test the wear resistance of the floor caster by certain Specifications casters in a certain speed, a certain load, friction floor samples under certain circumstances trajectory after the completion of the cumulative number of tests automatically shut down to observe the change of the sample, the sample assesses wear, with a total count of the experimental loop back lap times can be set, holding pressure time can be set and other functions.

Standards:

- EN 425-2002 (R2012): Resilient and Laminate Floor Coverings - Castor Chair Test Resilient floor coverings - Determination of chair casters effects.

- EN 985-2001 Textile floor coverings -. Castor chair test textile floor casters wheelchair test

- ISO 4918-2009 Resilient, textile, and laminate floor coverings - Castor chair test stratified elastic textile floor coverings - foot wheelchair test

- ISO 10581-2011 Resilient floor coverings - Homogeneous poly (vinyl chloride) floor covering - Specification Elastic Carpet - Homogeneous PVC carpet - Specification

- ANSI-NALFA-LF-01-2008.3.6 / ANSI-NALFA-LF-01-2011 Castor Chair Resistance-- North American Laminate Flooring Association chair casters anti-abrasion test

| Technical parameters | FCTM |

| Control | PLC control interface |

| Test function | Caster-resistant Flooring Effect Test / Resistant Floor Caster Friction Durability Test |

| Place the sample table size | Ø 800mm |

| Sample size | Ø 750mm |

| Load | 90kg |

| Test speed | rotary table (20 + 0 / -1) r / min, caster assembly (50 ± 1) r / min |

| Timer | (0 ~ 999999) times (25,000 times the standard can be set) |

| Run time control | After the rotation of the (180 ± 10) s, and maintain the platform stops (5 ± 2) s |

| Test way | A continuous cycle test |

| Power | 220V, 600W |

| Dimensions approximately | (L) 1460 × (D) 1000 × (H) 1750mm |

| Weight | About 180kg |

Product Categories

AGGREGATES (176)

ROCK MECHANICS (33)

ASPHALT/BITUMINOUS MIXTURE (110)

BITUMEN (64)

CONCRETE (161)

CEMENT - MORTAR (99)

CERAMIC (35)

SOIL (140)

SOIL MECHANICS (50)

METALS (33)

PLASTICS (32)

RUBBER (18)

TEXTILE - FABRIC - YARN (28)

NON-WOVEN FABRIC (2)

CARBOARD - PAPER & PACKING (38)

FILM (6)

INSULATOR (24)

FURNITURE (6)

MINING (54)

FOOD (30)

TABLET PRESS (2)

HEALTHCARE (313)

GENERAL EQUIPMENT (647)