Salt Corrosion Spray Test Chamber

- Product Code: HD-E808-60

Corrosion Resistance Tester adapted to

the surface treatment of various materials, including paint, electroplating,

organic and inorganic coating, anode processing, antirust oil, and so on, after

this anti-corrosive treatment to test the corrosion resistance of their

products. suitable for parts, electronic components, metal materials,

protective coatings, and industrial products.

Standard Parameters

|

Model |

HD-E808-60 |

|

Internal Size

(W*D*H) |

600*450*400mm |

|

External Size

(W*D*H) |

1060*580*1050mm |

|

Chamber material |

P.V.C rigid

plastic plate, thickness 8mm |

|

Sample tray |

Diameter 10mm

glass fiber rod, anti-rust V-shape plastic

steel to make sure sample in 15~30 degree inclined |

|

Temperature Range |

Room temperature ~

55℃ |

|

Temperature

Fluctuations |

≤±0.5℃ |

|

Temperature

Uniformity |

≤±2℃ |

|

Temperature

Precision |

±1℃ |

|

Spraying method |

Continuous and

Periodic spray type |

|

Test Chamber

Temperature |

Salt Spray Method

(NSS ACSS)35±1℃ |

|

Saturated air

Barrel Temperature |

Salt Spray Method

(NSS ACSS)47±1℃ |

|

Brine Temperature |

35℃±1℃ |

|

Spray Quantity |

1.0~2.0 ml / 80cm2

/ hr |

|

PH value |

Salt Spray Method

(NSS ACSS6.5~7.2) |

|

Lab Volume |

108L |

|

Brine Tank

Capacity |

25L |

|

Multiple Safety

Protection Devices |

Current discharge

protection, over pressure protection, over-temperature protection, overload

fuse protection |

|

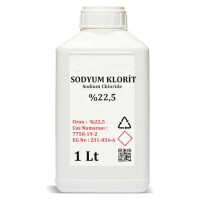

Accessories |

Testing Salt/

Measuring tank/Nozzle Equipment x 1 set |

|

Air source |

1HP Air pump

(provided by buyer) |

Experiment

method

ASTM B117-08, ISO 9227...

And IEC, MIL, DIN, ASTM, and other

standards equivalent to

Product Features

1.

Durable

hard 8 mm PVC construction, anti-corrosion, and easy to clean.

2.

Reservoirs

with mixing system on the stand.

3.

Separate

heating system apart from salt testing chamber to ensure the accurate result

and protect the circuit.

4.

Exposure

zone lined with corrosion-resistant PVC sheets.

5.

Clear the cover allows viewing of test conditions.

6.

Peaked the cover prevents the dripping of condensation onto samples.

7.

Water

seal and water level protection system.

8.

Heated

humidifying tower with air relief valve, adjustable tower tip to orient salt

fog.

9.

Automatic

DI water fills to humidifying tower.

10. Digital temperature control.

11. Integral over-protection on heaters.

12. Low water cut-off protection on

humidifying tower.